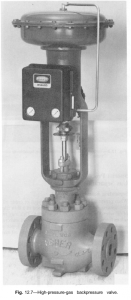

For an oil and gas separator to accomplish its primary functions, pressure must be maintained in the separator so that the liquid and gas can be discharged into their respective processing or gathering systems. Pressure is maintained on the separator by use of a gas backpressure valve on each separator or with one master backpressure valve that controls the pressure on a battery of two or more separators. Fig. 12.6 shows a typical low-pressure gas backpressure valve, and Fig. 12.7 shows a typical high-pressure gas backpressure valve used to maintain the desired pressure in separators.

The optimum pressure to maintain on a separator is the pressure that will result in the highest economic yield from the sale of the liquid and gaseous hydrocarbons. This optimum pressure can be calculated theoretically or determined by field tests.