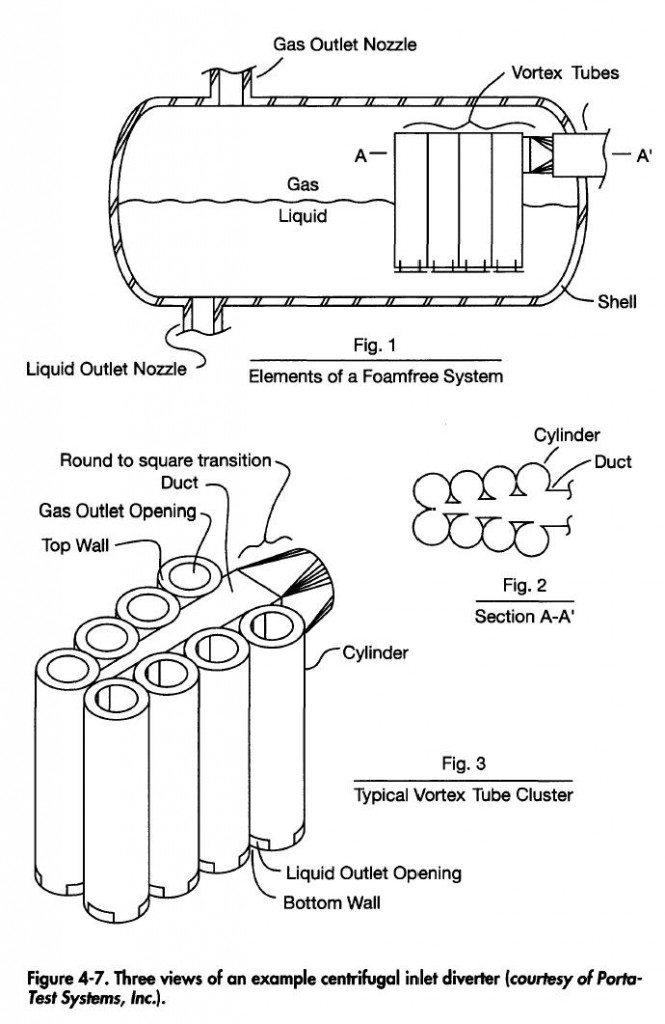

There are many types of inlet diverters. Two main types are baffle plates (shown in Figure 4-6) and centrifugal diverters (shown in Figure 4-7). A baffle plate can be a spherical dish, flat plate, angle iron, cone, or just about anything that will accomplish a rapid change in direction and velocity of the fluids and thus disengage the gas and liquid. The design of the baffles is governed principally by the structural supports required to resist the impact momentum load.

The advantage of using devices such as a half sphere or cone is that they create less disturbance than plates or angle iron, cutting down on re-entrainment or emulsifying problems. Centrifugal inlet diverters use centrifugal force, rather than mechanical agitation, to disengage the oil and gas. These devices can have a cyclonic chimney or may use a tangential fluid race around the walls. Centrifugal inlet diverters are proprietary but generally use an inlet nozzle sufficient to create a fluid velocity of about 20 fps. Centrifugal diverters work well in initial gas separation and help to prevent foaming in crudes.